¿Cuáles son los requisitos técnicos para la etapa de instalación y depuración del torno CNC?

Ambient temperature and humidity requirements. CNC lathes generally require a constant temperature of the environment to ensure the working accuracy of the machine tools, generally requiring a constant temperature of about 20 degrees Celsius. Practice has proved that during the high temperature period in summer, the failure rate of the CNC system is greatly increased, and it is easy to cause collision accidents. The humid environment will also reduce the reliability of the CNC lathe operation, so dehumidification measures should be taken in the CNC lathe environment to prevent short circuits, resulting in misoperation of the CNC system and collision accidents.

The standard debugging actions mainly include the following points:

1) When debugging the program, it is necessary to put the G00 speed selection switch on the F0 gear, so that the tool approaches the workpiece at a slower speed, otherwise, once the tool offset is wrong, the tool moves extremely quickly from the tool change point to the feed by G00 method. When the tool is at the point, there may be a strong collision with the workpiece, which makes the operator at a loss, and it is too late to remove the danger; on the contrary, when the tool is approached at a slower speed, even if the tool deviation is wrong, the operator has plenty of time to make adjustments.

2) When debugging the program, it is necessary to make the CNC lathe in the state of single-step execution. After the operator performs the previous block on the CNC lathe, it is necessary to check the correctness and rationality of the next block again, and make adjustments accordingly.

3) During the movement process of the CNC lathe, it is necessary for the operator to investigate the change of the tool coordinates on the screen and whether the coordinates of the end of the movement in the program and the coordinates of the actual movement of the tool are the same.

4) In the process of program debugging, the operator can put one finger on the cycle start button and the other finger on the side of the cycle hold button, so that the execution of the program can be stopped in time in a pressing time. At the same time, it's time to remember the orientation of the press button for emergencies.

5) Debugging phase of the program Use the computer to imitate the simulation function. With the development of computer skills, there are more and more simulation systems for CNC machining. Therefore, it can be used to start the inspection program to investigate the movement of the tool to confirm whether there is a possibility of a collision. Use the graphics that come with the CNC lathe to simulate the machining function. Generally, the more advanced CNC lathes have the function of graphic simulation processing. Before automatic processing, in order to prevent program errors from hitting the workpiece or chuck, the entire processing process can be simulated graphically to check whether the tool path is correct.

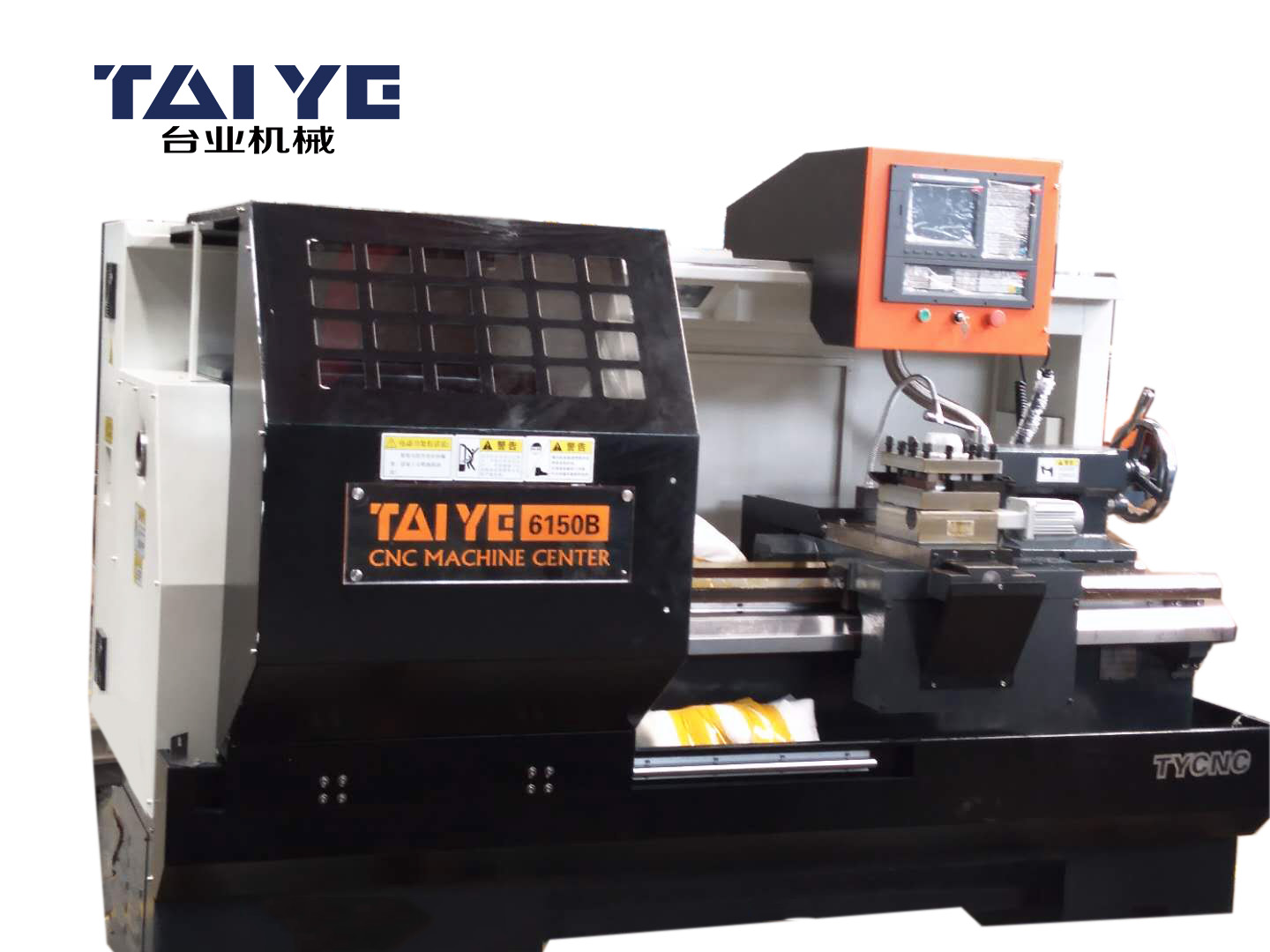

Taiye machine provide a full set of professional extrusion die equipment and extrusion dies, We have an aluminum extrusion die factory and a professional extrusion die equipment company in China. Our machine tools product include machining center, CNC lathe, wire cut EDM machine, EDM machine, Vacuum Furnace, etc., Each of taiye machines is professionally customized for the aluminum extrusion die process, with simple operation and high efficiency.

- Centro de mecanizado vertical de 3 ejes

- Centro de mecanizado vertical de línea dura de 3 ejes

- Centro de mecanizado vertical de 3 ejes 2 Lineal One Hard Line

- Centro de mecanizado vertical lineal de una línea de 3 ejes

- Horno de vacío de tratamiento térmico

- Horno de vacío de enfriamiento de aceite de tratamiento térmico

- Horno de vacío de enfriamiento de aire de tratamiento térmico